Rotating Equipment Overhaul

Our expert turbine engineers work efficiently to minimise outages and prevent degradation.

At Infinity Engineering Services, we perform all aspects of repairs and inspections for Gas turbines, Driven Unit and Auxiliary systems.

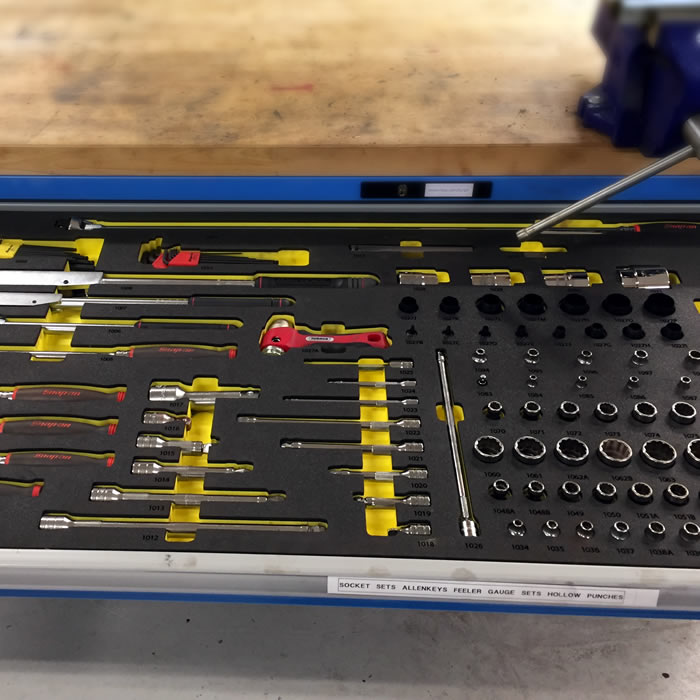

Overhaul services

We have an extensive range of turbine repair services:

- Major and minor turbine overhauls.

- Hot end/ Combustion life extension.

- Blade rejuvenation

- Power Turbine overhaul, On/Off site

- GT turbine remaining life assessments.

- Component repair or exchange.

- Rotor repair and balancing.

- Gearbox overhauls.

- Driven unit rotor overhauls

Our services may include collection from site, full disassembly, component integrity analysis, RCA investigations and Life extension proposals.

Gas Turbines

We offer affordable advice along with a comprehensive range support services for primary movers and rotating equipment driven units. You will have the choice of our high-quality engineering solutions for the majority of turbines in the industry. Our support range of engines and gas turbines include but are not limited to:

Our specialist engineers are OEM trained and certified. We cater for all your power generation, compression and mechanical drive application requirements. Our services include Installation/Commissioning, site/ workshop overhaul & service, remote monitoring, expert performance/fault analysis, and fleet data comparisons.

Siemens Industrial Fleet:

- SGT 100 (Typhoon)

- SGT 200 (Tornado)

- SGT 300 (Tempest)

- SGT-400 (Cyclone)

- SGT-500 (GT35)

- SGT-600 (GT10B)

- SGT-700 (GT10C)

- SGT-750

- SGT-800 (GTX)

- RustonTA

- Ruston TB5000

Siemens AGT:

- SGT A05 (501 Allison)

- SGT A20 (Avon)

- SGT A35 (RB211)

- SGT A65 (Trent)

(formally Rolls Royce Industrial)

GE:

- LM2500

- LM6000

- LMS100

- GT13E2

Solar:

- Saturn

- Taurus

- Centaur

- Mars

- Titan

Driven Equipment

Gas Compressors

Often bespoke repair solutions are required as opposed to standard OEM service or repair options. Infinity Engineering services are able to offer cost reductions by focussing on specific repair scopes reducing downtime and providing the most economical repair solutions. We are able to support process Gas compressors and all auxiliary systems inclusive of major service work such as Dry Gas Seals, Bearings and Rotor & Bundle exchange.

Gear Units

Our customers especially value our industrial gear units overhaul and inspection services due to our quality and affordability. We provide a number of services for the majority of gear unit designs from visual borescope inspection to full on/off site overhauls. A gear unit’s integrity being paramount to process sustainability is an essential inspection area. The choice of minor to major inspections offer you maximum flexibility in minimising outages within budgetary restrictions whilst ensuring integrity is maintained.

Generators

We offer an extensive range of generator services covering everything from portable to diesel energy converters. Our experience includes well-known industry brands designed to provide a reliable power supply, load recovery, clean power, better diagnostics, engine monitoring, and ease of synchronisation when operating.

Repairs

Our highly experienced personnel can resolve any situation on site. If your gas generator requires an emergency repair or workshop-based inspection, we can immediately offer you priority repair and testing to ensure your equipment’s prompt return to service.

The key to this service is flexibility and our ability to respond to our client’s needs in the most cost-effective and efficient method. We can work both on and offsite, offering a rapid response when required.

Outstanding Support for our gear unit reacting to major failure. One gearbox returned to operation successfully on schedule

Jean Piere Miello

Total

How we’re different...

Agile & Fluid Approach:

We deliver unbiased solution-orientated products and services that generate significantly higher reliability for your operations and assets

Effective Resources:

Highly experienced, multi-skilled engineers facilitate a reduction in manpower requirements and timely completions.

Scale up, Scale Down:

Condition-based repair or operational solution. Budget yet robust option or top tier unparalleled quality & most technologically advanced system & hardware.

Monitoring Performance:

Via our dynamic approach to operations and project management we continuously manage reduce delivery expenditure via dynamic focused project client interfacing.

On Time & Budget:

Remaining life assessments form an integral part of providing the most economical solution to our clients. With the unbiased innovative creativity, we pride ourselves on, we not only source the most efficient solutions & hardware but the end results are the most economical provisions.

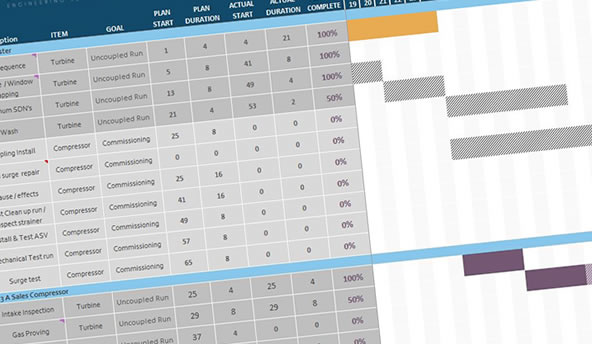

Our Approach to your project

Listen & Strategise:

- Focussed adherence to client briefs

- Incorporating quality & performance management

- Develop clear robust project plans

Engineer & Review:

- Engineer economical, mid-level & advance solution proposals

- Consult, review, amend & solidify brief compliance with the client

- Set timely objectives and verify schedule, methodology & KPI’s with the client

Execute & Deliver:

- Align - resources, pre-empt site requirements & logistical prerequisites

- Initiate project, report on performance, review to maintain schedule

- Complete, review, commission and performance test for client satisfaction.

Have some questions?

We are here to help, if we can answer any questions or offer advice please don’t hesitate to contact us on how our services may support you

Free Technical Consultation

We offer a no obligation informal consultancy call where we may discuss immediate operational issues and long and short term support requirements